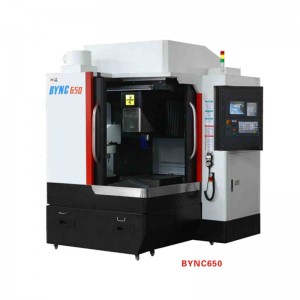

CNC milling machine with good precision

Machine Parameters

|

Model |

F-MMX-5SL |

|

bed dimension |

1473 x 320mm |

|

X axis of worktable stroke |

950mm ( maxi stroke is 980mm) |

|

Sliding saddle stroke (Y axis) |

380mm (maxi stroke is 400mm) |

|

Spindle box stroke (Z axis) |

415mm |

|

Elevator manual stroke |

380mm |

|

Table load bearing |

280KG(full stroke)/ 350KG( around center of worktable 400mm) |

|

T-slot size |

3 x 16 x 75mm |

|

principal axis |

BT40- Φ120 Taiwan brand |

|

main shaft speed |

8000rpm |

|

Spindle power |

3.75KW(rated) 5.5KW(overload) |

|

voltage |

380V |

|

frequency |

50/60 |

|

Positioning accuracy / repeat positioning accuracy

|

around center of worktable 400mm:0.009mm/±0.003mm |

|

full stroke 950mm:0.02mm、any 300mm/0.009mm |

|

|

Feed motor power |

X、Y/7Nm Z/15Nm with brake |

|

Fastest moving speed |

X、Y axes /12m/min Z axe /18m/min |

|

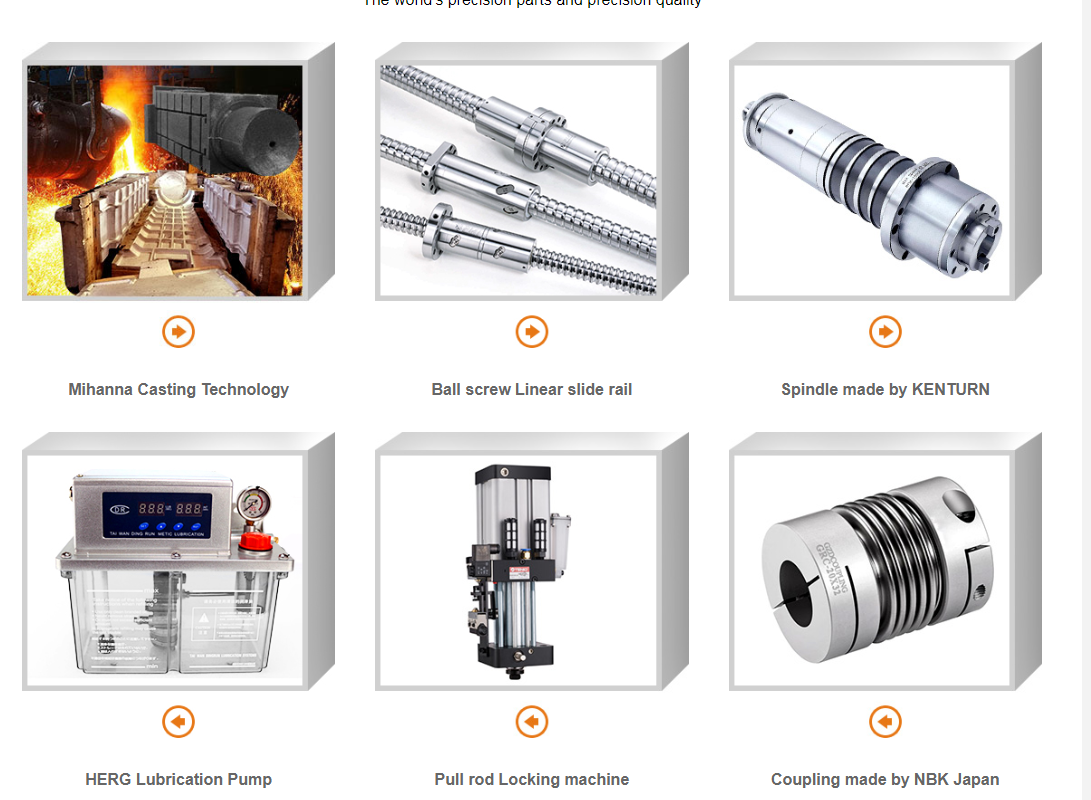

Ball wire rod type X shaft |

3208 Taiwan brand |

|

Ball wire rod type Y shaft |

3208 Taiwan brand |

|

Ball wire rod model Z shaft |

3205 Taiwan brand |

|

Rail X axis |

35 ball rail Taiwan brand |

|

Line rail Y axis |

35 ball rail Taiwan brand |

|

Rail Z axis |

30 ball rail Taiwan brand |

|

Clutch |

NBK, Japan brand |

|

Knife cylinder |

Taiwan brand |

|

Tool magazine |

Hat shape of 12 cutters Taiwan brand |

|

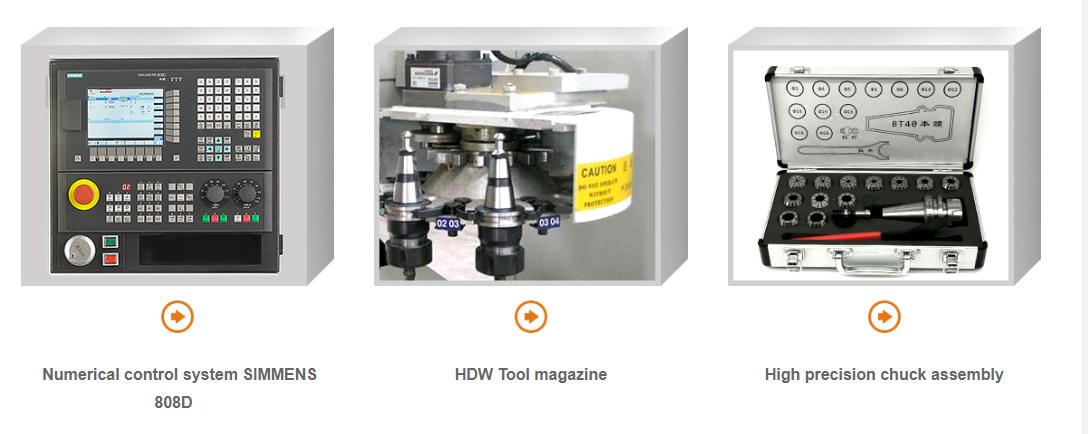

system |

Siemens 808D |

|

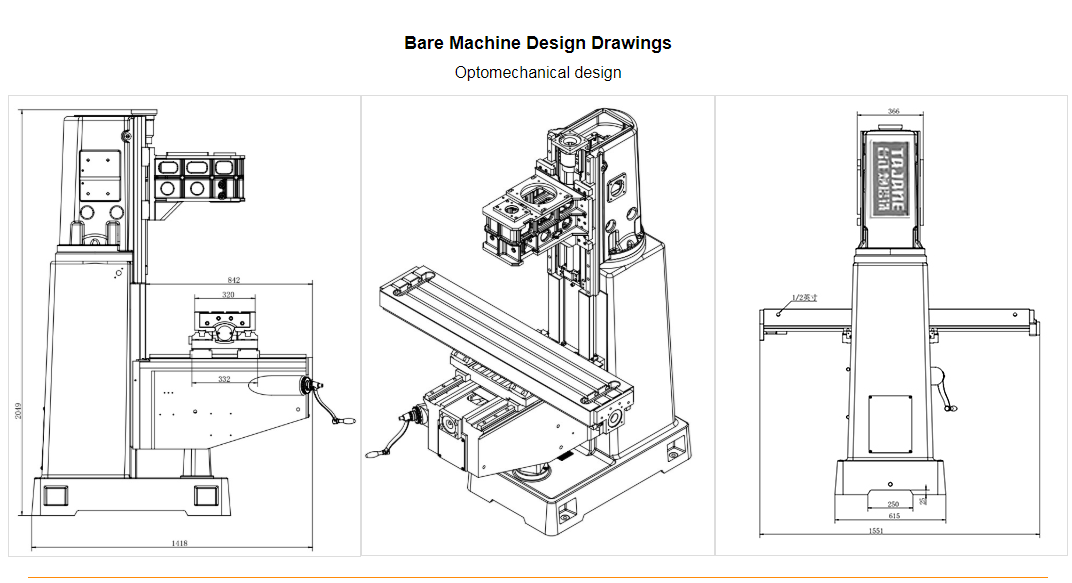

Machine tool shape dimension |

2000x1920x2500 |

|

weight |

2600kg |

|

Positioning accuracy X-directional full stroke / repeat positioning accuracy |

0.02mm/0.012mm |

|

Positioning accuracy / repeat location of 400mm in the middle of workbench |

0.009mm/0.006mm |

Machine Description

◎ The casting adopts the Meehanite casting process, and the bed is cast in one piece. Independent guide rail spindle box, strong rigidity and shock absorption.

◎ The machine use good ball rods and ball rails for three axes , would have big support,good precision ,fast move speed.

◎ The machine use Siemens 808D control system,image programming, type processing size, get auto processing , easy to operate.

◎ The machine has one hat shape tool magazine which could hold 12 pcs cutters, would process different workpieces: mill the flat face, keyway, drill hole, tape and processing in surfaces.

Accessories with machine

①Good precision 15 sets BT40 chucks ② QM160 a set precision flat nose pliers

③ one set precision fixtures with 58 parts ④one precision BT40 strong chuck

⑤100 pcs drill bits ⑥precision measure to find side of parts ⑦ protection cover

⑧ one anti-vibration set with 8 pcs parts ⑨ Coolant system