Professional China Drill Chuck - High quality precision processing PCD drill bits for special metals – FOREST

Professional China Drill Chuck - High quality precision processing PCD drill bits for special metals – FOREST Detail:

Product Description

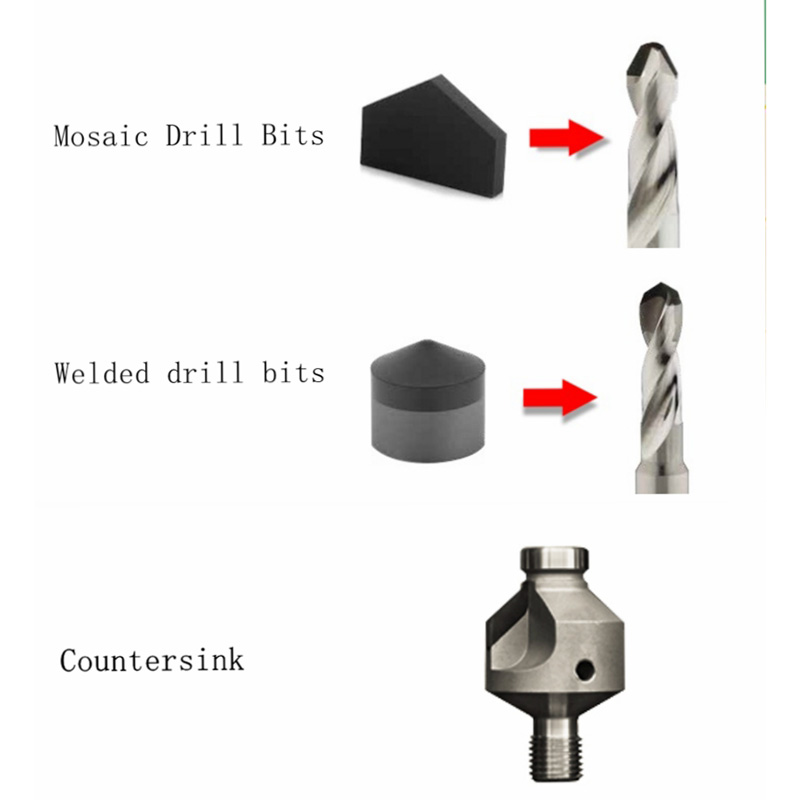

The preparation method of conventional PCD drill bits is usually to process a groove at the drill tip, use wire cutting to cut the PCD film deposited on the cemented carbide substrate to shape, and then weld it in the drill bit’s tip groove. In the early 1990s, welded PCD drill bits were used to drill the positioner holes on automobile engine pistons. The pistons are hypereutectic aluminum alloy castings (silicon content above 12%), and PCD drill bits must be used to process the required tools. Life, a drill can usually process 3,500 pairs of holes once sharpened (in fact, it may process 10,000 pairs of holes). However, the processing time of welded PCD drill bit is longer, and the processing cost per piece is higher. In addition, the cutting edge of the drill often suffers from welding failure under the action of high temperature, which leads to the damage of the entire drill. The use of integrally sintered PCD drill bits can better solve the above problems.

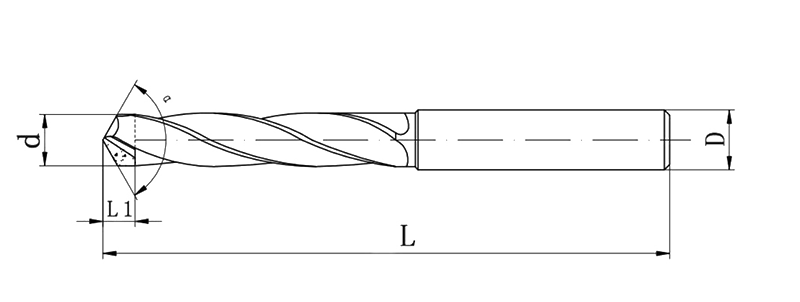

Structure Characters

Application areas: 3C, automotive, aerospace, etc.;

Applied materials: aluminum, magnesium, titanium, silicon and other non-ferrous metals; fiber materials, insulating materials, plastics, composite materials, etc.;

PCD drill bit category: PCD twist drill, PCD integral sintered drill, PCD countersink drill, PCD reaming drill compound cutter, PCD step drill, PCD straight groove drill, PCD deep hole drill, etc.

Advantages

Has super high hardness and super wear resistance;

Stable performance and lon g tool life;

Stable cutting performance, high processing efficiency;

A higher surface finish can be obtained.

Product detail pictures:

Related Product Guide:

We consistently carry out our spirit of Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for Professional China Drill Chuck - High quality precision processing PCD drill bits for special metals – FOREST, The product will supply to all over the world, such as: Kyrgyzstan, Croatia, Montreal, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

With a positive attitude of regard the market, regard the custom, regard the science, the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.