Swiss CNC Lathe Machine

Product Description

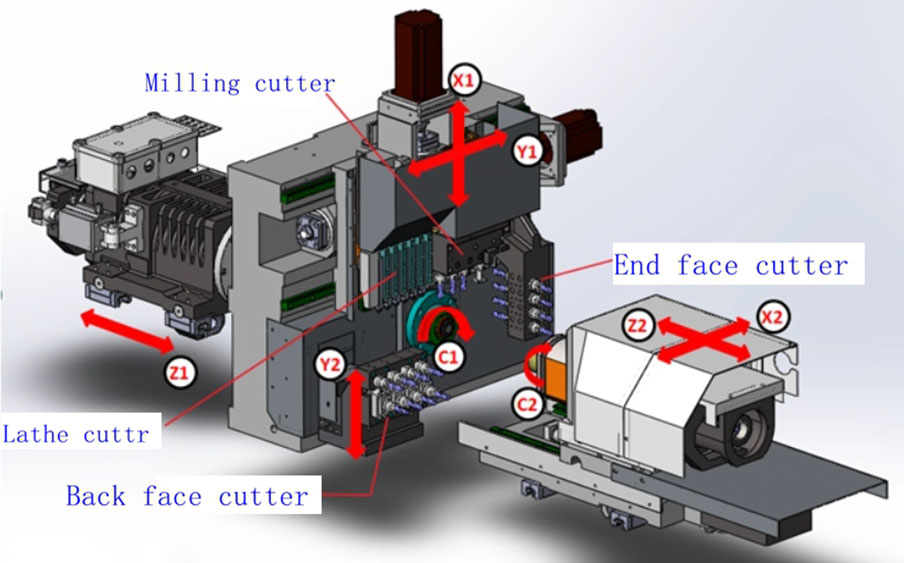

Swiss CNC Lathe Machine is called core-type CNC lathe, it can also be referred to as moving headstock type CNC automatic lathe, economical turning-milling compound machine tool or slitting lathe. It belongs to precision processing equipment, which can complete compound processing such as turning, milling, drilling, boring, tapping, and engraving at the same time. It is mainly used for batch processing of precision hardware and shaft special-shaped non-standard parts.

Swiss CNC Lathe Machine has a qualitative leap in machining efficiency and machining accuracy than CNC lathes. Thanks to the dual-axis arrangement of tools, the machining cycle time is greatly reduced. By shortening the tool exchange time between the gang tool and the opposed tool station, multiple tools Table overlap function, effective axis movement overlap function of thread chip, direct spindle indexing function during secondary processing, realize the shortening of idling time. Chip cutting tools have always been processed on the clamping part of the spindle and the workpiece to ensure constant processing accuracy. The maximum processing diameter of the core machine on the market is 38mm, which has a great advantage in the precision shaft processing market. This series of machine tools can be equipped with automatic feeding devices to realize fully automated production of a single machine tool, reducing labor costs and product defect rates. It is very suitable for mass production of precision shaft parts.

Widely used in instruments and meters, clocks, cameras, home appliances, medical equipment, hardware, communication electronics, automobiles, military industry, aerospace and other fields.

Features

1. No guide bushes/movable guide bushes can be switched according to the needs of the workpiece.

2. Oil-cooled electric spindles are more evenly cooled than air-cooled electric spindles, and more stable than mechanical spindles.

3. Absolute motor, automatically find the origin when the switch is turned on and off, saving time, trouble and labor.

4. Adopt NSK bearing, THK wire gauge/screw, high precision and long life.

5. The spindle is equipped with standard C-axis indexing and positioning, with complete functions and no routines.

|

Type |

Swiss CNC Lathe Machine |

|

Max processing OD range |

Φ3-12mm, Φ3-22mm, Φ3-25mm, Φ8-32mm |

|

Max processing length at one time |

180mm |

|

Maxi spindle drilling diameter |

Φ10mm |

|

Maxi spindle tapping diameter |

M10 |

|

Side tool max drilling diameter |

Φ8mm |

|

Side tool max tapping diameter |

M6 |

|

Main and sub spindle C axis indexing |

0.001° |

|

Z axis travel distance of main spindle |

280mm |

|

Spindle run-out tolerance |

≤0.004mm |

|

X/Y/Z repeated accuracy |

≤0.002mm |

|

X/Y/Z position accuracy |

≤0.003mm |

|

Min setting unit in system |

0.001mm |

|

Tools |

Buy separately |

|

Coolant system |

yes |

|

Air supply |

Above or equals to 0.4 Mpa |

|

Powe supply |

380V, 50HZ, 3 Phase , or customized |

|

Measure(L*W*H) |

1720*1040*1690 |

|

Weight |

1300KG |