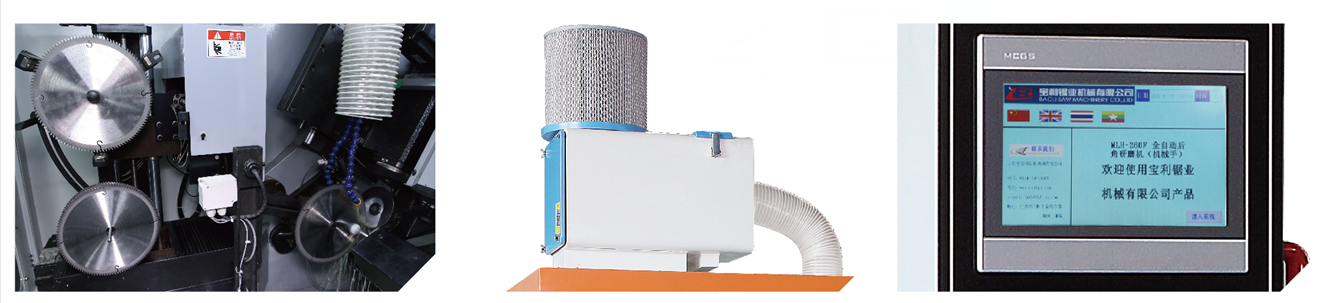

CNC auto polishing for saw blades production

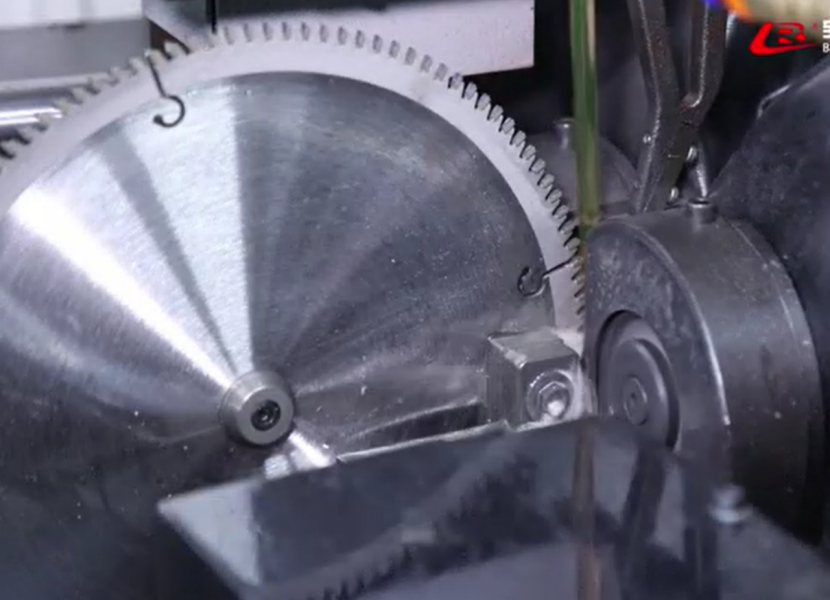

This machine is a special equipment for grinding the side angle of professional grade carbide circular saw blades.

Fully enclosed and environmentally friendly design, the manipulator automatically clamps the saw blade, and one person can operate 10-15 pieces of equipment.

Omron PLC and Mitsubishi servo motors are used to implement micro-feeding, the feeding amount can be set, and the equipment has good rigidity. Silver brand ball screws and precision-grade linear slides are used. The vertical grinding precision is high and the grinding wheel loss is low.

The program setting is flexible and diverse, and the feed position and the withdrawal position can be selected arbitrarily to realize various grinding methods.

| NO | Items | Parameter |

| 1 | Blade | Φ100-Φ315mm( Φ76-Φ269mm alternative designs) |

| 2 | Arbor Size | Φ12-Φ50mm ( customize orders available ) |

| 3 | Tooth Pitch | 5-65mm |

| 4 | Front Angle | -5°— +30° |

| 5 | Radial Angle | -5°— -5° |

| 6 | Perigon Angle | 0— 5° |

| 7 | Grinding edge width | 1.5-13 mm |

| 8 | Grinding edge thickness | 1.5-4 mm |

| 9 | Grinding edge length | 3-12 mm |

| 10 | Grinding precision | ≤ 0.02mm |

| 11 | Grinding speed | 20 PCS teeth/ min |

| 12 | Diamond wheel | Φ100xΦ20x4mm |

| 13 | Diamond wheel grit | 220# 280# or others |

| 14 | Working air pressure | ≥0.5Mpa |

| 15 | Total power | 3.5 KW |

| 16 | Weight | 1796 KG |

| 17 | Dimensions | 1805x1400x2603 mm |