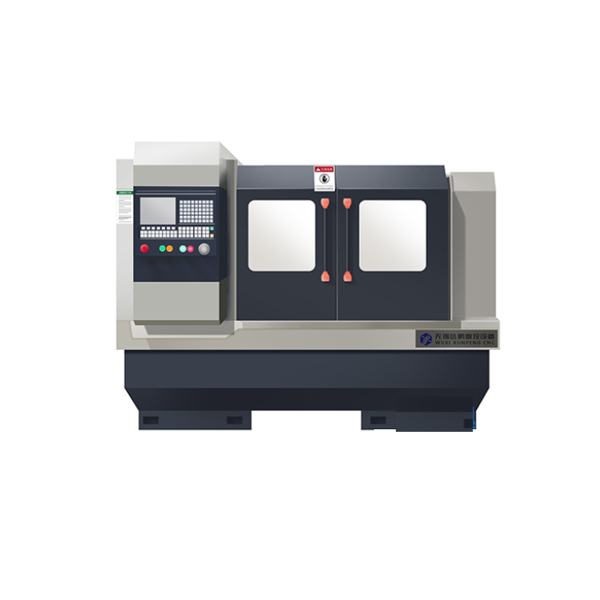

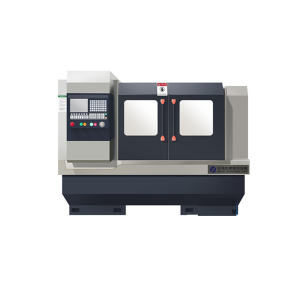

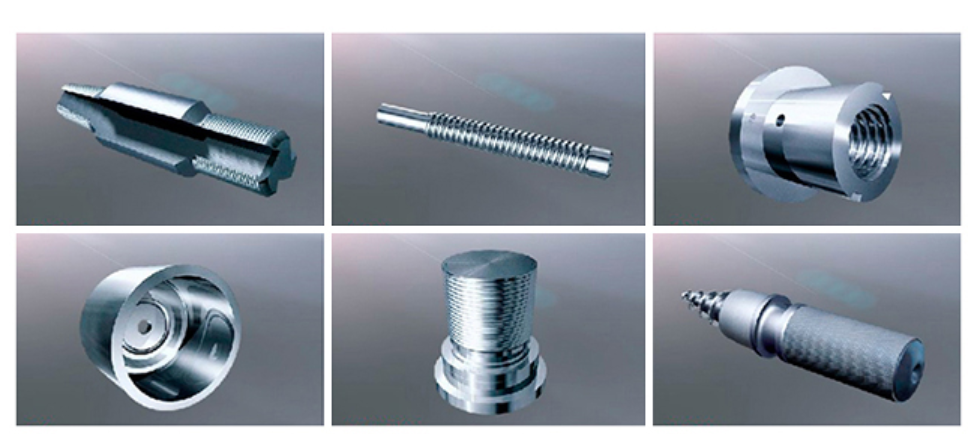

Flat rail CNC lathes rau ncej thiab disc qhov hlau ua haujlwm

CK6140 CNC tshuab dhos yog tsuas yog siv rau kev ua tiav thiab kev ua tiav ntawm cov ncej thiab cov khoom seem.Nws tuaj yeem ua cov txheej txheem sab hauv thiab sab nrauv cylindrical, conical nto, tig threads, tho qhov, reaming qhov thiab ntau yam nkhaus revolving lub cev;

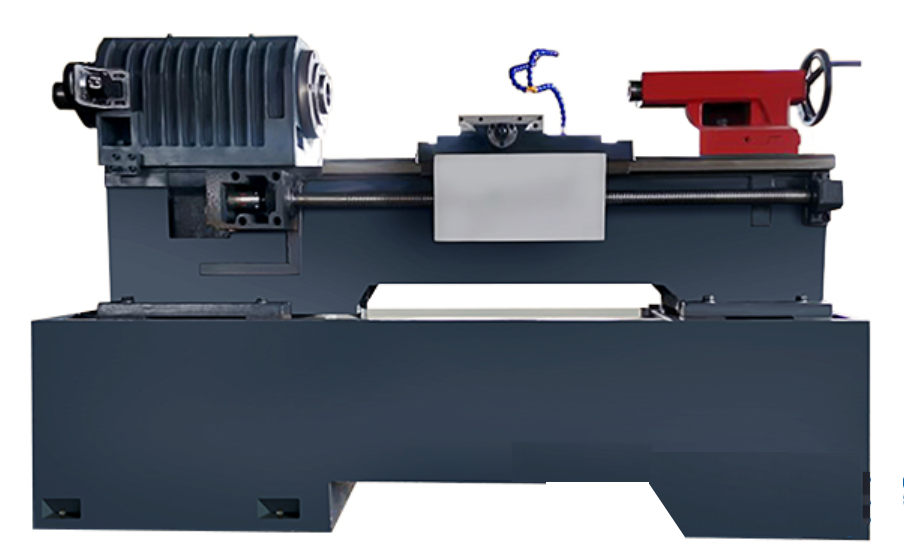

Lub spindle siv servo hluav taws xob hais, qis-ceev spindle nrog loj torque;

CK6140 muaj qhov zoo ntawm lub zog siab, zoo rigidity, loj precision cia, lub neej ntev, thiab lwm yam khoom siv nrog kev ua haujlwm siab thiab ntau yam.Siv lub tshuab dhos CNC no, tsuav yog qhov kev xav tau ntawm lub tshuab ua haujlwm tau muab tso ua ke rau hauv ib qho kev pabcuam machining raws li cov hom ntawv teev tseg, random inputs rau hauv lub microcomputer, thiab tom qab ntawd los ntawm lub kaw lus keyboard, nias lub workpiece tus lej thiab tus yuam sij pib, lub tshuab dhos. yuav cia li ua kom tiav lub voj voog sab nrauv ntawm qhov chaw nyob rau hauv kev tswj ntawm qhov system, puab lub qhov, kawg lub ntsej muag, kauj ruam, grooving, chamfering, thiab lwm yam, thiab muaj tsis siv neeg tig muaj nuj nqi ntawm arc, nkhaus, xov thiab taper.

Nta:

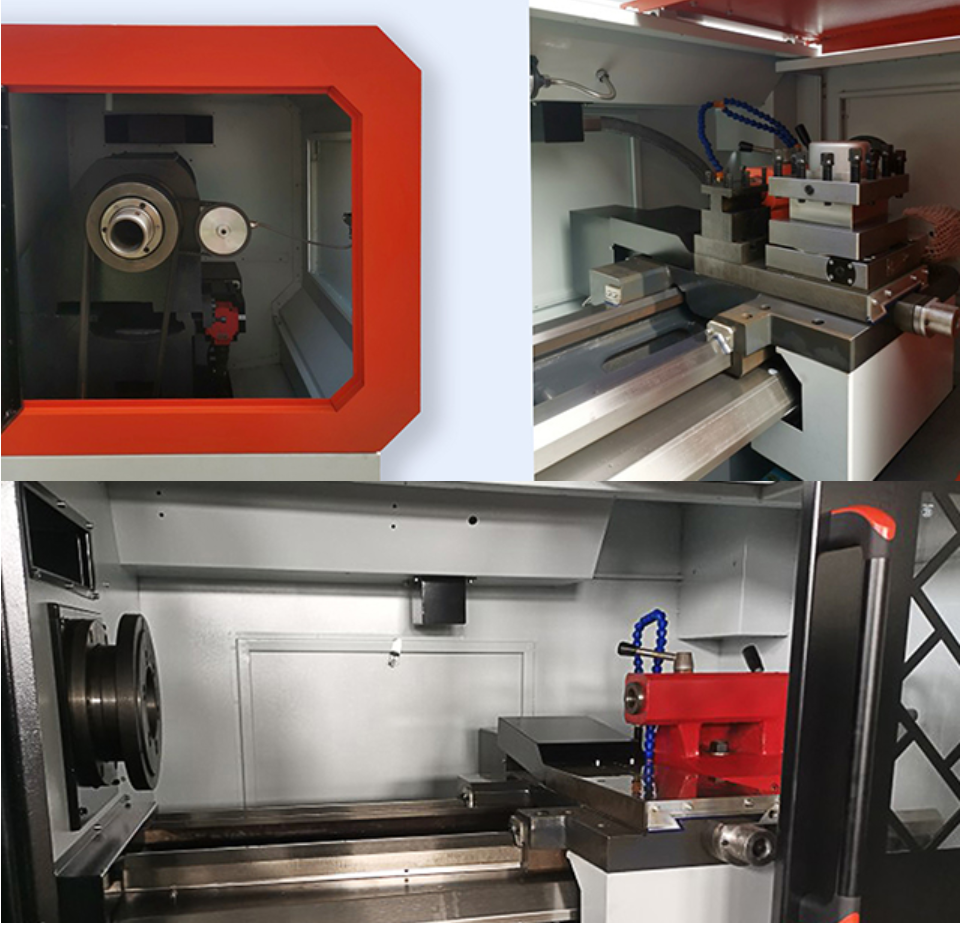

1. Muaj phau ntawv qhia, hydraulic thiab pneumatic xaiv rau chuck thiab tailstock.

2. Ob lub tshuab cuab yeej qhia kev tsheb ciav hlau thiab lub eeb qhia kev tsheb ciav hlau yog ua los ntawm cov lus qhia nyuaj ua los ntawm cov khoom siv tshwj xeeb.Tom qab high-frequency quenching, lawv yog super nyuaj thiab hnav-resistant, ruaj thiab muaj zoo machining raug.

3. Cov ncej muaj plaub qhov chaw nres tsheb, rau lub chaw nres tsheb, ntsug thiab kab rov tav rau kev xaiv.Nws txais yuav qhov kawg ntawm cov hniav phaj qhov chaw, thiab tuaj yeem xaiv cov riam kab, nrog rau siab rov ua qhov tseeb.

4. Lub tailstock muaj cov cuab yeej ceev nrawm nrog kev ua haujlwm siab.Muaj ib qho khoom siv hauv lub tes tsho tailstock los tiv thaiv lub laum me ntsis los ntawm kev sib hloov, uas tsis txhob muaj kev puas tsuaj rau lub taper ntawm lub puab qhov ntawm lub tes tsho tailstock vim kev sib hloov ntawm lub laum me ntsis tshwm sim los ntawm misoperation, thiab zoo tiv thaiv cov tailstock Cheebtsam.

5. Lub optimized tsim ntawm headstock yog haum rau txoj siav ntawm disc thiab ncej.Nws tuaj yeem ua cov kab ncaj nraim, arcs, metric thiab nti threads, thiab ntau txoj xov xov.Nws yog tsim rau tig discs thiab shafts nrog complex duab thiab siab precision yuav tsum.Kev ua haujlwm hauv chav kawm.

6. Lub kaw lus tswj tus lej txais cov npe nrov hauv tsev thiab txawv teb chaws xws li Guangshu system lossis Kaiendi.Nws tuaj yeem tsav los ntawm hybrid stepping lub cev muaj zog lossis AC servo lub cev muaj zog, thiab lwm lub tshuab kuj tuaj yeem xaiv raws li cov neeg siv khoom xav tau.

7. Cov ntawv qhia kev tsheb ciav hlau tau nruab nrog cov cuab yeej scraping los tiv thaiv cov kev taw qhia kev tsheb ciav hlau los ntawm kev corroded los ntawm hlau filings thiab coolant, thiab pab txhawb kev tu cov hlau filings.

8. Yooj yim rau kev khiav lag luam, tshwj xeeb tshaj yog tsim nyog rau kev ua cov khoom siv los yog cov khoom siv high-precision loj, thiab nws kuj yog thawj qhov kev xaiv rau CNC kev qhia.

Khoom zoo:

1. Lub tshuab cuab yeej muaj qhov ua tau zoo, thiab cov spindle txais HRB high-precision ob lub pob bearing txhawb, uas muaj suab nrov, siab precision thiab zoo stability.

2. Lub txaj qhia rail yog finely hauv av tom qab ultrasonic quenching, nrog siab hardness thiab zoo rigidity.

3. Cov khoom siv hluav taws xob plaub-chaw nres tsheb tau txais qhov tseeb ntawm qhov chaw ntawm lub phaj, thiab qhov rov ua dua qhov tseeb yog siab.

4. Lub tailstock muaj cov cuab yeej ceev nrawm nrog kev ua haujlwm siab.Muaj ib qho khoom siv hauv lub tes tsho tailstock los tiv thaiv lub laum me ntsis los ntawm kev sib hloov, uas tsis txhob muaj kev puas tsuaj rau lub taper ntawm lub puab qhov ntawm lub tes tsho tailstock vim kev sib hloov ntawm lub laum me ntsis tshwm sim los ntawm misoperation, thiab zoo tiv thaiv cov tailstock Cheebtsam.

5. Lub kaw lus tswj tus lej txais cov npe nrov hauv tsev thiab txawv teb chaws xws li Guangshu system lossis Kaiendi.Nws tuaj yeem tsav los ntawm hybrid stepping lub cev muaj zog lossis AC servo lub cev muaj zog, thiab lwm lub tshuab kuj tuaj yeem xaiv raws li cov neeg siv khoom xav tau.

6. Yooj yim rau kev khiav lag luam, tshwj xeeb tshaj yog tsim nyog rau kev ua cov khoom siv los yog cov khoom siv high-precision loj, thiab nws kuj yog CNC qhia.

Tiv tauj nrog peb kom paub ntau ntxiv tshuab dhos

| TIAB SA 6140 | TIAB SA 6150 | TIAB SA 6180 | |

| Max viav txoj kab uas hla saum txaj (mm) | 400 | 500 | 800 |

| Qhov siab tshaj viav vias ntawm lub cuab yeej ncej (mm) | 220 | 280 | 480 |

| Max ntev ntawm workpiece (mm) | 750/1000/1500 | 1000/1500/3000 | 900/1300/1700/2700 |

| Dav ntawm txoj kev tsheb ciav hlau (mm) | 330 | 450 | 600-750 |

| X axis mus ncig (mm) | 250 | 265 | 400 |

| Z axis mus ncig (mm) | 750/1000/1500 | 1000/1500/3000 | 1500 |

| Spindle ceev (rpm) | Tsis muaj zog 150-2500 | 50-1500 Nws | 25-850 Nws |

| Spindle qhov (mm) | Φ 60 | Φ82 ua | Φ100/130 |

| Nos ntawm cutter | 4/6/8 | 4/6 | 4/6 |

| Repetition pointing raug | 0.01mm ib | 0.01 ib | 0.01 ib |

| Pub ceev hauv X axis | 4000 | 4000 | 4000 |

| Pub ceev hauv Z axis | 6000 | 8000 | 6000 |

| Pub rau hauv ib lub cuter | 0.005-100 | 0.005-100 | 0.005-100 |

| Kev ua haujlwm raug | TSI 6-7 | TSI 6-7 | TSI 6-7 |

| Roughness | 1.6 | 1.6 | 1.6 |

| Tailstock tes tsho taper | MT4 | MT5 | MT6 |

| Tailstock tes tsho dia (mm) | 70 | 75 | 100 |

| Tailstock tes tsho mus ncig (mm) | 120 | 170 | 250 |

| Ntsuas (mm) | 2130/2520/3050x1400x1680 | 2800/3100/4100x1650x1650 | 3600/4100/5600x1600x1780 |

| Qhov hnyav (KG) | 1600/1800/2200 | 2800/3100/5000 | 4400/5100/6000 |

| Hwj chim | 380V, 3Phase, 50HZ lossis customized | ||