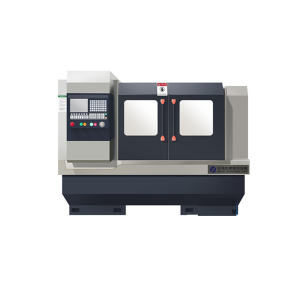

Rov qab dual-spindle tig chaw (Machining txiav ntau lawm kab)

MW series ob-spindle ob-turret tig-milling compound ua tshuab dhos yog nruab nrog lub qhov rooj-hom mechanical caj npab.Cov khoom no muaj ob npaug-spindle, ob-turret, ob chav C-axis, ob chav Y-axis, 8-axis tswj, 2 teeb ntawm 4-axis txuas, kaw-voj tswj, Ob lub turrets yog tig-milling compound servo cov cuab yeej tuav nrog drilling thiab milling cov cuab yeej, thiab dual spindles yog built-in servo motorized spindles, thiab kaw-voj tswj ntawm high-precision tawm tswv yim Cheebtsam paub lub high-precision indexing ntawm ob C axes, qhov kev daws teeb meem ntawm ob spindles yog 0.001 degrees, lub dual spindles tuaj yeem txuas ntxiv indexed thiab muab tso rau ntawm ib qho kev ntsuas, thiab tuaj yeem paub txog ya tsheb noj thiab pub mis rau hauv cov txheej txheem ntawm kev ua haujlwm, thiab ua kom tiav txoj kev tig thiab indexing eccentric drilling ntawm complex rotary qhov chaw nrog ib tug noj txiav, positioning milling, teb. milling, thiab tag nrho cov txheej txheem ntawm high-speed slotting, kom paub txog cov txheej txheem ntawm tag nrho cov txheej txheem nyob rau hauv lub siab ntawm tag nrho cov seem, uas yog, lub workpiece tuaj yeem ua tiav tag nrho lossis feem ntau ntawm cov txheej txheem ntawm ib lub tshuab cuab yeej.Nws thawj zaug clamps lub workpiece ntawm thawj ntxaiv los ua kom tiav kev sib xyaw ua ke thiab milling ua, thiab tus neeg tswj xyuas tau hloov lub workpiece mus rau qhov thib ob spindle rau qhov thib ob tig thiab milling ua ke ua ke.Ib lub tshuab cuab yeej paub txog cov txheej txheem ua haujlwm ntawm ob lub tshuab cuab yeej, nrog kev ua haujlwm siab thiab ua haujlwm siab.siab.Cov cuab yeej siv tshuab tuaj yeem siv dav hauv aerospace, tsheb, nkoj, khoom siv hluav taws xob, khoom siv engineering, kho vajtse li qub, precision pwm, kev lag luam tub rog thiab lwm yam lag luam.Lub siab-rigidity thiab tshav kub-phooj ywg txaj qauv yog tshwj xeeb tsim rau nws, thiab lub zog-absorbing peev xwm ntawm tig yog nce.Ob lub turrets tau nruab nrog 12-chaw nres tsheb cov cuab yeej tuav, uas zoo heev txhim kho kev ua haujlwm zoo.

Technical Parameters

| NO | Cov khoom | Kev piav qhia |

| 1 | Maxi nrug ntawm spindle xaus | 7 35mm |

| 2 | Mini nrug ntawm spindle xaus | 210 hli |

| 3 | Maxi txoj kab uas hla ntawm cov khoom siv rods | Φ52 hli |

| 4 | Maxi txoj kab uas hla ntawm daim hlau cov ntaub ntawv | Φ160 hli |

| 5 | X1 / X2 axes stroke | 160/135 hli |

| 6 | X1 / X2 axes ceev noj | 24/24m / min |

| 7 | Z1 / Z2 / B strokes | 503/503/525 hli |

| 8 | Z1 / Z2 ceev noj | 24/24m / min |

| 9 | Spindle Maxi ceev | 6000 rpm ib |

| 10 | Spindle lub cev muaj zog LR | 7.5 / 7.5 |

| 11 | Spindle qhov diameter | Φ56 hli |

| 12 | Spindle center qhov siab | 1100 hli |

| 13 | Spindle qhov ntswg loj | JIS A2-5 |

| 14 | Cutter Model (nce thiab nqis) | 12 chaw nres tsheb Turret |

| 15 | Up turret Y axes stroke | ± 135 (kev xaiv xaiv) |

| 16 | Sab nraud txoj kab uas hla cutters | 25 * 25mm |

| 17 | Khaub ncaws tho txawv | Φ40 hli |

| 18 | X / Z axes pab lub cev muaj zog | 1.8 TSI / 1.8 KW |

| 19 | X / Z axes pab lub cev muaj zog tig | 3000/3000 rpm |

| 20 | Coolant tank ntim | 150 L |

| 21 | Ntsuas (L * W * H) tsis muaj khib nyiab cais | 2100 * 1550 * 2440 hli |